DISSOLVED AIR FLOATATION

Dissolved Air Floatation is one of the most effective method to remove suspended solids (TSS), biochemical oxygen demand (BOD5), and oils and greases (O&G) from a wastewater stream.

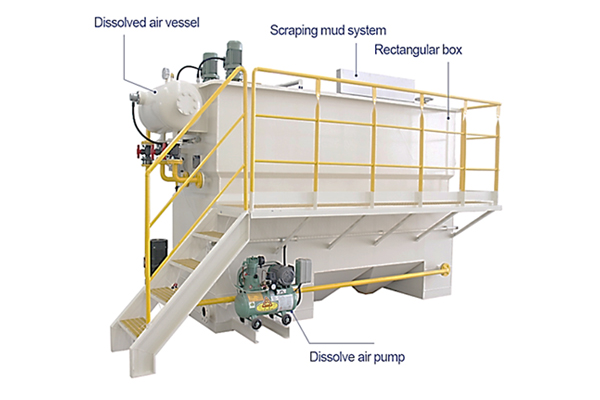

As the name suggests, dissolved air flotation works by injecting pressurized air into a recycle stream, which is made of already-clarified DAF liquid waste. The system then combines and mixes the recycle stream with incoming wastewater in an internal contact chamber.

In that chamber, the dissolved air comes out of the DAF liquid solution in the form of micron-sized bubbles. These bubbles attach to the contaminants in the wastewater and together they rise to the surface and form a floating bed of material. A surface skimmer removes this conglomeration of material and puts it in an internal hopper for further processing.